The Shed 105, November — December 2022

Sold Out

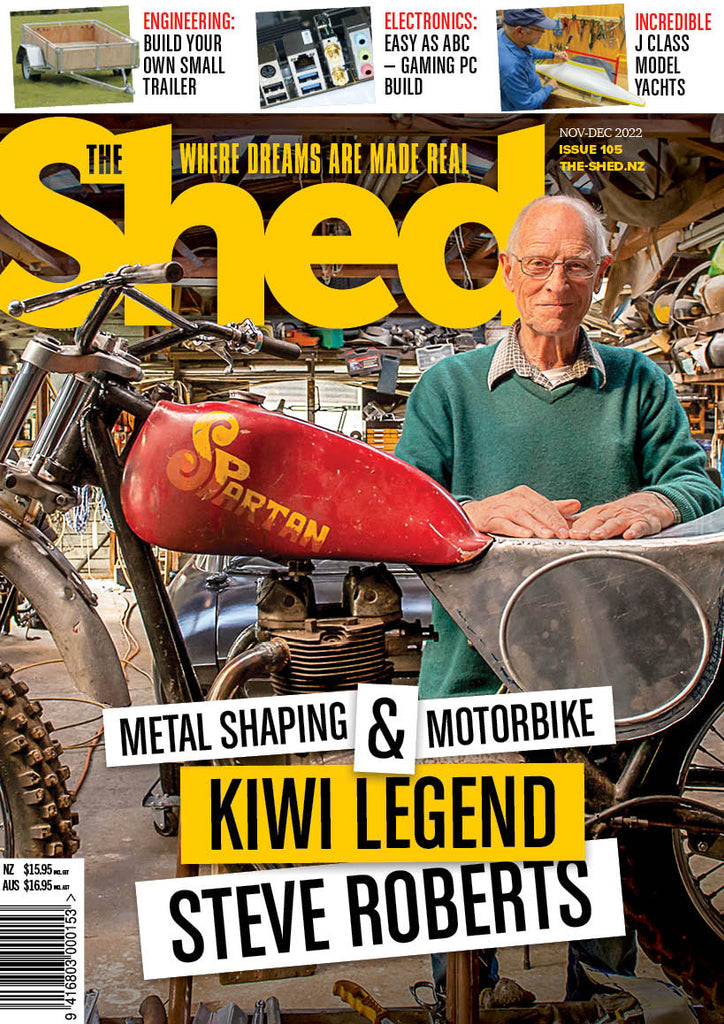

Legendary panel maker

The unassuming Steve Roberts has been called everything from artist and magician to guru of alloy; he himself is more comfortable with the handle ‘tin basher’

Our cover story this issue is on a legend of metal shaping and motorbikes, Steve Roberts. Steve is one of this country’s most respected and admired craftsmen in these fields, and we made the journey to Whanganui to catch up with him in his shed.

“In person, Steve’s mild-mannered countenance seems at odds with the loud and often showy world of motorsports. It is his contributions to the design, engineering, and performance of two-wheel and four-wheel vehicles, on and off track, that speak volumes. Steve’s virtuosity with metal is legend among motoring enthusiasts and racing professionals around the world and, after six decades in the trade, he is still a go-to guy for out-of-the-box thinking and superior craftsmanship. His output has been prodigious; his innovations groundbreaking; his production values and eye for detail next level. Incredibly, most of his work has been conjured, beaten, and bent with ‘basic tools’ — an indispensable 1920s lathe, a homebuilt press, and an ancient wheeling machine — from a modest shed he once shared with his family’s horses, on the outskirts of Whanganui.”

Engineering/Welding:

Build your own trailer — part one

Our From The Shed Archives article this issue is part one of a series on how to build your own small trailer. If you are sick of shabby imported models that rust and fall apart quickly, this is the project for you. Buy all the parts locally and build one yourself. This two-part project was written by trailer maker Tony Cullen.

“With minor variations, I have built a standard 1200mm x 1800mm domestic trailer with a solid frame of box section or rectangular hollow section (RHS) mild steel. The frame is braced by angle-iron cross members, and has a sturdy, ply wooden deck.”

Model-making:

J-class model yachts — scaled-down fun

Nigel Young discovers a model yacht club that undertakes some America’s Cup racing without all the fuss and expense.

“In 1996, Christchurch Model Yacht Club member Dave Heanly entered ‘J-1’ into a race that had already begun. Made of fibreglass and built by Heanly, Norm Sissons, and Hugh Hobden, the boat was in no way disadvantaged by the handicap, as ‘she went like a rocket. Shamrock sped past everyone and finished first!’

“The result launched the J-class as a fun, competitive, yet relatively inexpensive hobby. It was based on the J-class Ranger yacht that successfully defended the 1937 America’s Cup, defeating the British challenger Endeavour II 4–0 at Newport, Rhode Island. It was the last time J-class yachts would race for the America’s Cup.”

Electronics:

Build a computer? Sure you can

A father and son duo turn into superheroes for a young family member after building him a custom-made gaming computer from seven key components and a lot of satisfying tinkering.

“My son Bodhi and I recently became the most admired grandfather/uncle combo on Earth by building my grandson his own, custom-made gaming computer.

“Charlie had saved $1000 and was ready to buy his first gaming computer, which would open the way for a whole level of games not playable on a Playstation or Xbox. Sadly, Charlie wasn’t even half-way there. A new one (and there are good reasons not to buy second-hand) would cost more than $2000.

I knew that I could put one together out of new components for considerably less than that.”

Building a kitset log house — part two

Mal gets some hands-on help from the kit makers

A helping hand from ‘the cavalry’ boosts morale and lightens the load for Mal’s kitset log house build. He’s well into completing the build, but he’s not there just yet — but it’s close.

“Already having shouted myself a decent Skilsaw, a Paslode framing nailer, a Hitachi battery drill plus impact driver, and a welding machine from the two garage builds, I now needed a decent drop saw. No problem.

“However, I also needed an additional ‘something’ to cut the 8x6-inch American logs cleanly in one cut. No drop saw was big enough. So I had the bright idea of getting a 300mm Hitachi metal cut-off saw, popping on the biggest (fire)wood saw blade I could get, 405mm, and using that — health and safety were always involved, of course.”

Bronze casting

The David Reid Technique of Lost wax bronze casting — Part 3

Out of the noise, the heat, and the molten metal, the alchemist reveals his creation. We complete our three part how-to this issue with the melting and then pouring of the bronze to complete the series. The forge gets up to very high temperatures and a lot of care is required but this final stage is relatively straightforward.

“After several entertaining hours building the ceramic shell and the furnace — David is quite a raconteur — it was time to hatch the phoenix’s egg. The roar of the torch and the orange-red glow of the furnace were nothing if not exciting. Expectations high, we followed the master through his sleights of hand — he overheated one of them, quickly changing the short tongs for longer ones.”

Toy-making:

Metal cars and trucks — building toys that stand the test of time

Coen Smit is fed up with rubbish toys that fall apart way too soon and wants to build toys for his grandchildren that stand the test of time and the test of some of the tough customers who use them.

“As I grow older, I’m disappointed by the increasing proliferation of the throwaway society. We have been conditioned to believe that the things we buy all have inbuilt use-by dates. Everything is built to a price with the implicit expectation it will not last. Corners are continually cut to save on materials and production time, and we’re expected to always seek the newest incarnation of the products we purchase. This trend pervades almost everything we buy from clothing and tools to white goods and toys.”

Software test: Alibre 101 — part two

How to change an existing file to create similar, but slightly different, parts. A step-by-step guide to changing the socket already created in part one to a new 12-point (or double-hex) version

Bob Hulme is well into testing out this software and showing us how easy it is to use to get the technical drawing we need to get parts manufactured. The final part of this test will be in the following issue of The Shed, Issue No. 106.

“In part one, we created a 17mm A/F ½-inch-drive deep socket. This part two shows how to use the work already done to create a slightly different socket. This is one of the advantages of digital drawing — there is no need to start from scratch. By modifying an existing file we can quickly create similar, but slightly different, parts. If changes to a part need to be made, then it is easy too. No rubbing out required!

“The objective, for this article, is to change the socket already created so we have a new 12-point (or double-hex) version. Once the change is made we can save the file as a different part. Then there will be two digital drawings on our file — both the same size sockets, but one is single-hex while the other is double-hex. Same, but different.”

Off the Grid:

Letting go — some lessons in when it’s time to let go

Murray Grimwood has one of those sheds where there are bits and pieces scattered for that moment when you just might need them. But sometimes you need to say goodbye to tools, parts, and even close friends.

“Sometimes there are no major projects to report between magazine deadlines; life, routine maintenance, and other things get in the way. The past couple of months have been such a time, but I’ve also been doing something I’m not very good at: letting go. I’m damned good at collecting; not so good at letting go.”

Electronics: Tales for Makers — part three

An introduction to machine learning with Neuton.AI

In this issue’s Tales for Makers, Enrico Miglino steps back slightly from the game project to introduce some new software that you will need for the game.

“In this episode of Tales for Makers, we will temporarily leave Ray searching for his son Tommy, and move on to something more technical. We will look at the basis of the Neuton Tiny ML platform, and why I strongly suggest using this framework for applications such as the Drone Patrol project.”

Military vehicles:

Huge and unique collection finally sees the light of day

At nearly 70 years of age, Don Pelvin is still doing a form of national service, bringing military vehicles back to life and sharing them with the public.

Easter 2022 was the date when Don brought his vast collection out for the public to view at a fundraising event in Timaru. To say military vehicle collectors and the public were dumbstruck is something of a real understatement. No one had ever seen a collection as vast and remarkable as this.

“Don has been quietly working away in his spare time for 15 years, pursuing his hobby of finding and restoring rare military vehicles. For most of that time, few people were aware of the steadily growing collection of vehicles in the sheds behind his Timaru home, or the dedication that has gone into restoring them to their prime. Don had been working away so quietly that when his collection was revealed at its first public showing in Timaru, other collectors were amazed.”

The Shed Shrink:

Boof the lizard and Ruby Tuesday - companionship can come in many guises

Mark Seek, our resident mental-health expert, chats to us about mates and the fact that you just don’t know where they are going to appear from.

“Recently, I was asked to look after a friend’s dog — not a big deal; just to go around and give him his food, fill up his water bowl, and then give him the odd pat, as a bit of human company would be good for him. Little did I know at the time that I actually needed a bit of dog company and it would be good for me also. I have owned several large dogs over the years and have often thought about giving a rescue dog a forever home.”

Back o’ The Shed:

La Niña blues — the weather gods laugh at Jude’s plans

This magazine’s founder Jude Woodside is living the good life in his rural shed — but is he? The weather and the council are out to spoil his happy days.

“Spring is here! The bleating of the lambs in the fields next door and my fruit trees all abloom tell me that.

“But the rain doesn’t seem to want to let up. In fact, it hasn’t really stopped raining since May. I know this because that was when I started on the foundations for my shed. I managed to get two trenches of the four I need dug for the foundation. Since then, it’s simply been too wet to get a digger anywhere near the site. The sight of near-continuous grey skies is hardly conducive to springtime gaiety.”